The Future of Professional Indoor Cultivation

The Indoor Growing Compartment (IGC) is far more than just a trend: More and more professional growers are relying on modular grow rooms to achieve consistently high yields independent of climate, location, and lease duration.

Modular cultivation combines mobility, scalability, and discretion – perfect prerequisites for legalized markets, research projects, or pilot productions. CarbonActive delivers with the Indoor Growing Compartment (IGC) a turnkey solution that unites all critical parameters – light, climate, air exchange, control – in one modular system.

This guide shows you how to plan, procure, and operate professional grow rooms step by step, what advantages modular growing spaces offer over tents or halls, and why the CarbonActive IGC accelerates your implementation.

Advantages of Modular Grow Rooms

An IGC as a cultivation solution is superior in many ways:

Mobility and Flexibility: IGCs come pre-assembled, can be dismantled when needed and rebuilt at new locations. Follow your business during location changes without losses.

Fast Commissioning: Connect power, water, and ventilation, plug in – done. Turn-key concepts save months of construction time. Installation takes only a few days.

Scalability: With each additional module, production area grows linearly. Combine multiple IGC modules or couple them to a central climate unit. Starting with 4 IGCs, central air conditioning becomes worthwhile.

Discretion: IGCs appear inconspicuous from the outside, are odor-tight and sound-insulated. Perfect for professional cultivation in business parks.

Consistent Microclimate: Insulated sandwich panels and precise climate technology create stable temperature and humidity profiles that are precisely controllable.

GMP or GAP Compatibility: Clean surfaces and modular ventilation meet pharmaceutical standards more easily than makeshift rooms.

Challenges with Modular Grow Rooms

Even though modular cultivation has many advantages, typical pitfalls must be avoided:

Heat Removal: Compact modular construction requires precise climate technology. High-performance ventilation with energy recovery up to 80% is integrated.

Humidity Management: With high plant density, transpiration increases. The IGC features integrated dehumidification systems in the Professional configuration level.

Energy Efficiency: Thanks to energy recovery and EC technology, heating and cooling costs are drastically reduced.

Installation Requirements: 4m ceiling height and 32A to 57A power connection at 400V are required.

Professional Installation: For warranty claims, installation must be performed by CarbonActive. On-site visit for assessment: $3,300-5,500.

CarbonActive IGC – Concept and Construction

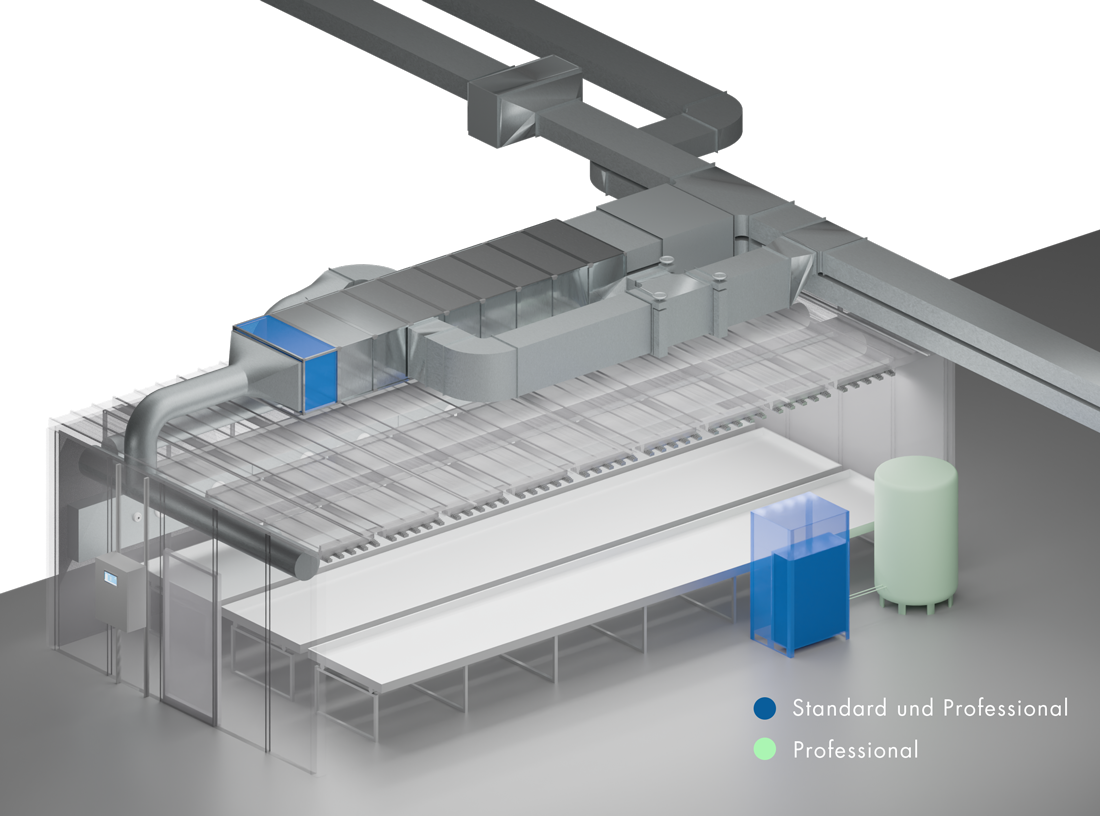

The CarbonActive IGC is a prefabricated indoor module that is inserted as a free-standing unit into virtually any building. The structure is based on hot-dip galvanized frame profiles, insulated sandwich panels, and a semi-loop climate system that efficiently mixes fresh and exhaust air.

Turn-Key Ready: Pre-assembled climate and lighting technology, including Siemens S7 control and CE-compliant control cabinet.

Flexible Equipment: Customers choose between three configuration levels according to budget and requirements.

Modularly Networkable: Multiple IGCs can be operated via a central AHU or individually, ideal for research series or strain separation.

Fast Assembly: Setup within a few days; delivery time: 8 weeks.

IGC Configuration Levels in Detail

Basic Configuration Level (from $91,300)

The Basic configuration level includes energy recovery and enables optimal climate under cold to moderate outdoor conditions.

Ideal for: Startup phase or seasonal operation (>70% of the year optimal temperature)

Upgradeable: Later upgrade to Standard or Professional without production interruption

Special Feature: In midsummer, nighttime lamp operation is recommended

Standard Configuration Level

Standard includes, in addition to energy recovery, an industrial air conditioning system with outdoor unit for year-round optimal temperatures.

Advantage: Constant temperatures even in summer Disadvantage: More variable climate in hot months compared to Professional

Professional Configuration Level (up to $168,300)

Professional offers the most consistent climate conditions through integrated dehumidification in the Air-Handling-Unit.

Special Features:

- Low-variation climate control

- Integrated dehumidification technology works continuously

- Lower energy consumption through clever combination of cooling and heating

- Optimal for crop steering on rockwool

- ROI: Amortization already after first harvest

Technical Specifications and Modules

A look at the data sheet shows the industrial precision of the IGC:

Dimensions: Standard module with customer-specific dimensions possible

Growing Area: Two stainless steel tables, together approx. 366 ft² (34 m²) usable area

Lighting System: SanLight LEDs recommended (other manufacturers integrable), 900 µmol/m²/sec standard intensity

Ventilation: Semi-loop system with AHU, heating, cooling, dehumidification, and energy recovery up to 80%

Control: Siemens CPU, touch display, remote maintenance via VPN, alarm notifications via SMS/email

Materials: Powder-coated panels, food approval, wipeable

Optional Equipment: Electrically height-adjustable lamp holders and adjustable side ventilations

Thanks to this integration density, IGCs effortlessly meet GMP guidelines for medicinal cannabis or HACCP standards for herb production.

Planning and Sizing a Modular Grow Room

A successful professional grow room begins with precise specification definition:

Target Crop and Variety: Photoperiod, height, root space, and CO₂ requirements determine interior height and table geometry.

Light Requirements: 900 µmol/m²/sec is recommended, as higher intensities cause disproportionately higher climate costs.

Climate Load: LED waste heat + plant evaporation = latent and sensible load. This determines AHU cooling capacity.

Energy Sources: Electricity, gas, or heat pump? A heat recovery circuit significantly shortens ROI.

Permits: Fire protection classes, food license, or pharmaceutical GMP should be clarified early.

CarbonActive supports with design-assist and detailed cost and feasibility analysis.

Installation and Commissioning

Preparation

- 4m (13 ft) ceiling height required

- 400V three-phase power: 32A (Basic) to 57A (Standard/Professional)

- Water connection for climate technology

- Load-bearing foundation

Assembly Process

- Delivery: Pre-fabricated modules via special transport

- Installation: Only by CarbonActive technicians for warranty claim

- Commissioning: Setup of Siemens PLC, calibration of all systems

- Training: Instruction in touch panel and remote maintenance

Operation

- Fully automatic climate control via Siemens control

- 24/7 data logging for GMP batch documentation

- Remote maintenance and alarms via VPN/SMS/email

- Tool-free filter change via quick-release fasteners

Economic Efficiency and Energy Efficiency

Modular grow rooms are considered capital-intensive – but the cost structure shifts in favor of lower operating costs:

Energy: Energy recovery up to 80% drastically reduces heating costs, climate performance by up to 30%

Labor Time: Compact floor space minimizes walking distances, fully automatic systems reduce manual work

Financing: Leasing rates are often immediately tax-deductible, construction costs are only depreciated

Yield Density: Approx. $2,600/m² net growing area enables higher g/m² yields than in halls

ROI Analysis: Professional configuration level amortizes already after the first harvest despite higher acquisition costs through optimized operating costs and higher yields.

Sustainability and GMP Conformity

IGC panels are recyclable, ventilation uses EC technology for high efficiency. The clean surfaces allow validations according to EU-GMP to be achieved faster than with conventional conversions.

Combined with LED lighting and energy recovery, your modular grow room significantly undershoots the CO₂ footprint of traditional indoor projects.

Practical Example: Standard IGC Module

| Key Figure | Value | Details |

|---|---|---|

| Investment | $91,300 – $168,300 | Depending on configuration level |

| Cost per m² | $2,600/m² | Net growing area |

| Growing Area | ~366 ft² (34 m²) | Two stainless steel tables |

| Energy Recovery | Up to 80% | All configuration levels |

| Delivery Time | 8 weeks | Standard |

| Installation | Few days | Only by CarbonActive |

| Warranty | Full warranty | With professional installation |

Strategies for Switching to Modular Grow Rooms

Phase-In Strategy: Start with a Basic IGC, continue running existing systems in parallel until process stability is achieved.

Configuration Level Planning: Start with Basic in fall, upgrade to Standard/Professional in spring with first revenues.

Scaling Concept: Starting with 4 IGCs, central air conditioning becomes worthwhile with significant cost savings.

Personnel Training: IGCs require less manual climate control but more process data management.

CO₂ Optimization: Modular construction enables targeted CO₂ enrichment with better efficiency.

SOP Development: Document every step for GMP audits and continuous optimization.

Central Air Conditioning for Multiple Installations

Starting with 4 IGCs, designing central air conditioning becomes economically interesting:

Advantages:

- Significant cost savings in installation and operation

- Central monitoring and maintenance of all modules

- Higher energy efficiency through load distribution

- Reduced redundancy in climate components

Planning: CarbonActive develops individual solutions according to building characteristics and requirements.

Conclusion

Whether pilot farm, research project, or GMP production – modular grow rooms with CarbonActive IGC open completely new horizons for indoor farmers. You receive a mobile, energy-efficient, and standards-compliant unit that can be assembled in days and quickly amortizes through optimized operating costs.

Modular cultivation transforms your business into a flexible, scalable platform – and CarbonActive provides the tool for it.