01

02

03

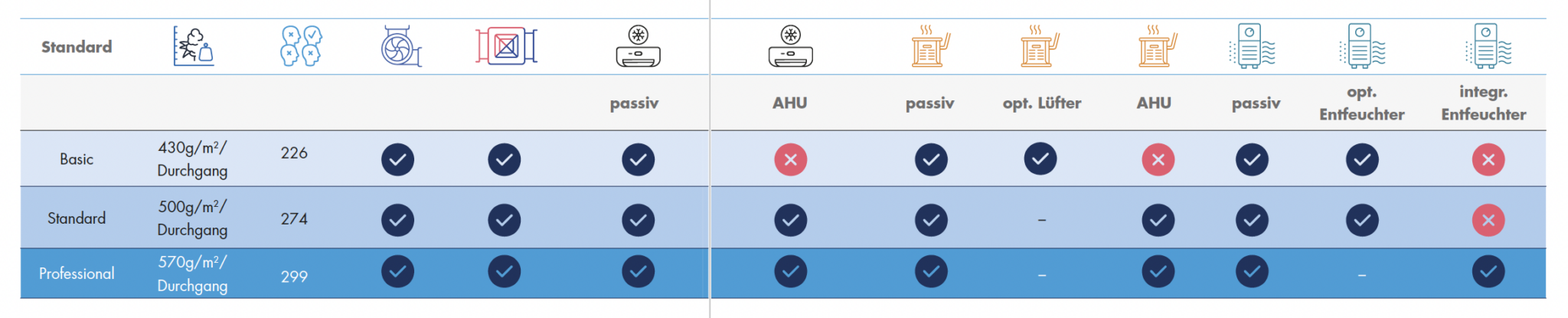

The IGC is CarbonActive's solution for scalable, high-performance cultivation rooms. The IGC is configurable in 3 climate control variants and with several upgrades.

Every detail of the lighting, climate, tables, and ventilation is perfectly harmonized to maximize crop yield and quality.

Thanks to the standardized design, there is no loss of planning time and costs when installing an IGC. The installation of an IGC only takes a few days.

We highly recommend professional installation by CarbonActive. Without it, we cannot offer a warranty for the IGC.

To enable cultivation projects to grow with their increasing turnover and to keep initial investments low, the IGC can initially be installed in the “Basic” variant so that it can later be upgraded to the “Standard” or “Professional” variant with an industrial climate control unit. This saves initial costs and approval work for the installation of the outdoor climate control unit.

Delivery time: 8 weeks.

* We recommend SanLight, but can integrate any lamp on request.

A ceiling height of 4 m is required. The Basic model requires a 32A power connection, while the Standard and Professional models require a 32A and an additional 25A power connection.

To secure the IGC guarantee, CarbonActive takes care of the installation - this first requires an on-site visit to take stock. The costs for this are between CHF 3,000 and CHF 5,000, depending on the location, and will be offset against the installation costs later. Location-dependent transportation costs may also be incurred.

from CHF 83,000 + installation and delivery

from CHF 2,370/m² net cultivation area

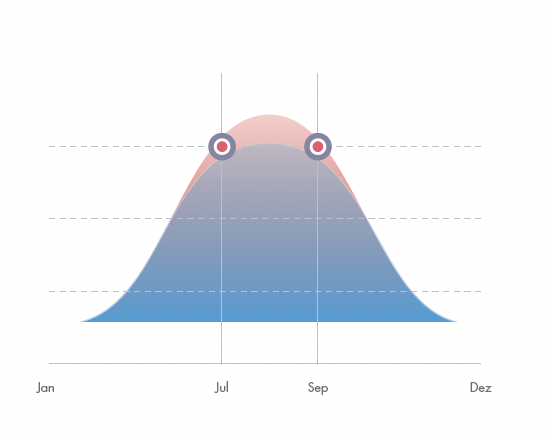

The “Basic” variant includes our energy recovery system to effectively cool, dehumidify and keep the heat in the cultivation room's air supply and exhaust air for approx. 70 % of the year without any other aids.

At the height of summer, it is advisable to run the lighting in Basic at night and let the dark phase take place during the day. At high outside temperatures, Basic no longer dehumidifies sufficiently and additional dehumidifiers become necessary. This can be remedied by resistant genetics with airy growth, so that work can be carried out even at higher air humidity levels without a high risk of mold.

Basic can later be upgraded to Standard and Professional. We already install an empty air handling unit housing so that the climate control unit can be integrated without any significant interruption to production.

In addition to energy recovery, the “Standard” variant also includes an industrial climate control system with outdoor unit - this means that the desired temperatures can be maintained in the cultivation room's even in warm summer. Together with an additional dehumidifier or even a heating system (we will be happy to explain in detail why this works), the optimum air humidity can also be maintained at all times. The only disadvantage of this setup compared to the Professional variants is the more fluctuating climate in the hot months.

It is not possible to upgrade to the “Professional” variant at a later date.

In addition to energy recovery and an industrial climate control system, the “Professional” variants also include a dehumidifier integrated into the air handling unit to keep both the air temperature and the relative humidity in the room constant with minimal fluctuation. Thanks to a clever combination of cooling and heating, this works with less energy input than the “STANDARD” variants and is therefore cheaper to maintain. This is achieved by using a cold water tank.

It is not possible to upgrade to the “Professional” variant at a later date.

From 4 IGCs, it is worth designing and realizing a central climate control system for all IGCs in order to reduce initial and operational costs.

The “Basic” IGC provides an optimum climate for the plants in cold to moderate outdoor conditions. When starting cultivation in the fall, the Basic equipment can be used for excellent cultivation until spring.

In spring, the first sales can then be upgraded to “Standard” or “Professional” to ensure the desired temperatures and relative humidity values in the cultivation even in summer.

While an additional dehumidifier may be necessary with the “Standard” IGC to ensure sufficient dehumidification performance at moderately warm but not yet hot outside temperatures, dehumidification is integrated into the overall system in the “Professional” IGC.

The direct integration of our in-house developed dehumidification technology in the “Professional” IGC ensures a low-fluctuation climate. In contrast, the use of an additional dehumidifier in the “Standard” IGC leads to higher fluctuations in relative humidity due to its design. This is due to the fact that conventional dehumidifiers switch on and off - whereby a rest period must be taken after each switch-off process. Automatic defrosting can also lead to longer downtimes.

Our integrated dehumidification solution in the “Professional” IGC works continuously and therefore regulates the relative air humidity with very little fluctuation.

All our IGCs can be ordered with optional electrically height-adjustable lighting mounts and electrically adjustable lateral ventilation.

We always advise cultivation with 900 µmol / m² / sec, as higher light intensities also make climate control installations more expensive by a similar factor to the increase in light intensity. For many reasons, it is more worthwhile to install additional IGCs than to increase the output of the individual IGCs when rents are higher than in Zurich city center or Manhattan.

As more constant or optimal climatic conditions can be created with increasing variants, the plants in the higher variants also have more opportunities to develop their yield potential. For example, the “Professional” variant is perfect for cultivation on rockwool using crop steering strategies thanks to its constant, low-fluctuation climate.

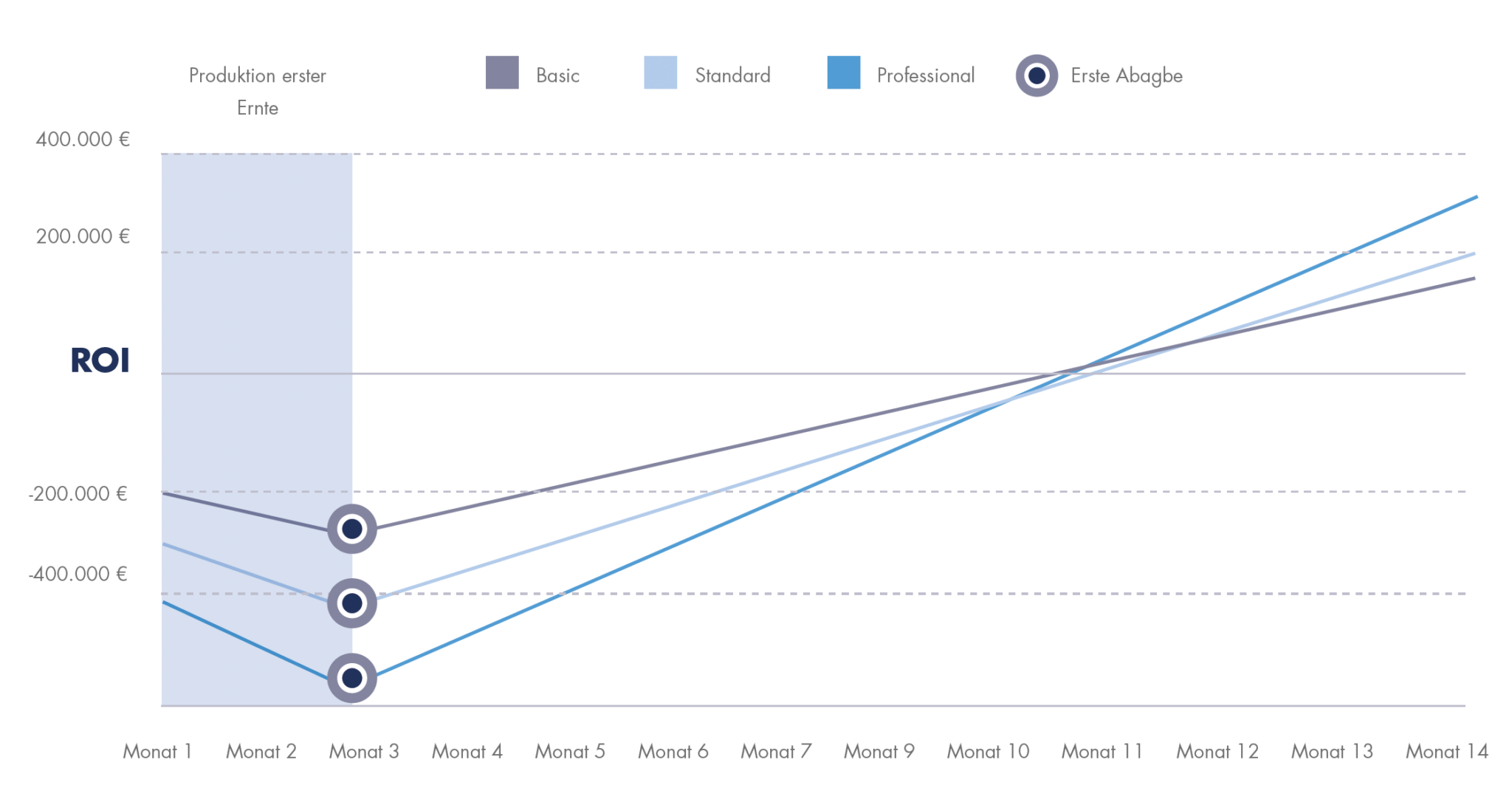

Since an IGC in the “Professional” variant costs almost twice as much as the “Basic” variant, we have created a financial model, taking into account production costs and other costs such as salary and rent for the dispensary, to show how the potentially higher yields per m² of cultivation area affect cash flow.

If you take into account that the production costs for the first batch are incurred after the initial investment and the available capital continues to fall as a result, the investment in the high variants is amortized after the first delivery.

Therefore, as long as you get rid of the material produced, the repayment periods of the individual variants do not differ greatly from one another. After that, however, you will save on expenses through more efficient operation and/or lower operational costs and generate more income through higher yields, leading to higher operating results.

We would be happy to go through our financial model with all the specific assumptions with you in a consultation and also adapt it to your requirements.

Book an appointment with our expert Lorenz Minks as soon as possible.

Copyright © 2025 CarbonActive Holding AG

Um Ihnen ein optimales Erlebnis zu bieten, verwenden wir Technologien wie Cookies, um Geräteinformationen zu speichern und/oder darauf zuzugreifen. Wenn Sie diesen Technologien zustimmen, können wir Daten wie Ihr Surfverhalten oder eindeutige IDs auf dieser Website verarbeiten. Wenn Sie Ihre Zustimmung nicht erteilen oder zurückziehen, können bestimmte Merkmale und Funktionen beeinträchtigt werden.